Senior Lecturer of Processes and Equipment of Chemical and Petroleum-Refineries Department

Sumy State University

2, Rymskogo-Korsakova St.

40007 Sumy, Ukraine

E-mail: [email protected]

Personal websites: https://www.researchgate.net/profile/Artem_rtyukhov/, http://ua.linkedin.com/pub/artem-artyukhov/3b/87b/5a4

EDUCATION:

2005–2008: Ph.D. Studies, speciality 05.17.08, «Сhemical TechnologyProcesses and Equipment», Sumy State University, Sumy,Ukraine

2002–2004: graduate studies, Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy, Ukraine

2004–2005: Undergraduate Studies, Mechanical Engineering, Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy, Ukraine

DEGREES:

2013: Associate Professor of Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy,Ukraine

2009: Candidate of Sciences (Ph.D.) speciality 05.17.08, «Сhemical TechnologyProcesses and Equipment», Sumy State University, Sumy,Ukraine

2005: Master (graduate), «Equipment of Chemical Manufactures and Enterprises of Building Materials» Sumy State University, Sumy, Ukraine

2004: Bachelor of Science in Mechanical Engineering, «Equipment of Chemical Manufactures and Enterprises of Building Materials» Sumy State University, Sumy, Ukraine

PH.D. THESIS:

Hydrodynamic factors of granulation devices with a decreased hight of granules flight

The dissertation deals with the theoretical and experimental research of hydrodynamic indicators of one or two phase flows in the operating space of small-sized vortical devices with the variable area of an operating space intersection.

At present enterprises are specialized in the manufacturing of different granular products from solutions and fusions using granulation towers. This equipment requires great money input for its making, technical maintenance and repair. It is rather complex to be produced and maintained because of its dimensions. Setting up of new enterprises based on the manufacturing of granular products by means of false boiling vortex layer granulators is one of the ways expenses of decline for producing granular porous products and increasing their quality. To achieve this goal we must introduce the newest developments of modern science and technology.

The methods of computation of operating space hydrodynamics in vortical devices were worked out based on physical and mathematic models. Hydrodynamic characteristics of flows were defined and the effects of starting, technological and geometrical conditions on the sizes of granulation devices were estimated. An algorithm and method of engineering calculation of vortical type vehicles is created. The new method of granular production and new small-sized high efficient devices for granulation were put forward and patented. Experimental and industrial installation of vortical devices was made alongside with analysis of marketable products. The results proved the high efficiency of the devices made.

Keywords: GRANULATION, HYDRODYNAMICS OF FLOWS, VORTICAL GRANULATOR, MODELLING, SIZES.

PROFESSIONAL EXPERIENCE:

july 2011 – present: Senior Lecturer at Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy, Ukraine

september 2009 – may 2011: Senior Instructor at Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy, Ukraine

2006 – august 2009: Assistant Lecturerat Processes and Equipment of Chemical and Petroleum-Refineries Department, Sumy State University, Sumy, Ukraine

LIST OF MAIN RECENT PUBLICATIONS:

Аrtyukhov А.E. Production of granules with special properties in small-sized vortex devices/ А.E.Аrtyukhov, V.I. Sklabinskyi // Modern scientific research and their practical application. – 2012. - Volume J31207. – рр. 138-147. http://essuir.sumdu.edu.ua/handle/123456789/29349

Artyukhov A.E. The prospects of granules getting with the specific properties in small-sized vortex devices / A.E. Artyukhov //In proceeding of: VII International Conference «Strategy of Quality in Industry and Education», special number of International Scientific Journal Acta Universitatis Pontica Euxinus, Varna, Bulgaria, Volume: vol. 3., pp. 19-20. http://essuir.sumdu.edu.ua/handle/123456789/26420

N.A. Kochergin, A.E. Artyukhov, V.I. Sklabinskyi, V.A. Osipov. Estimation factors of the power influencing and determination of terms of dispersion phase equilibrium in small in vehicles for creation of granules with the special properties, Visnyk of the East Ukrainian university named after Volodymyr Dal, 2010. Vol. 7(154), pp. 105-112 [in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24959

K.V. Korobchenko,A.E. Artyukhov, V.I. Sklabinskyi, O.O. Lyaposchenko. Hydrodynamicsofvehicleswithvorticalandhighturbulencestreams, ScientificworksoftheOdessanationalacademyoffoodtechnologies, 2010, Vol.37, pp. 310-315 [in Russian] http://essuir.sumdu.edu.ua/handle/123456789/24796

V.I. Sklabinskyi, A.E. Artyukhov. Determination of hydrodynamic characteristics of the dispersed phase in the small vortex devices, Visnyk of Kremenchuk Mykhaylo Ostrogradskiy State Polytechnic University, 2009, Vol. 6 (59), pp. 196-201 [in Russian] http://essuir.sumdu.edu.ua/handle/123456789/25904

A.E. Artyukhov, O.O. Lyaposchenko, V.I. Sklabinskyi. Prospectsofgranuleswiththespecialpropertiesproductioninsmallvorticalvehicles, VisnykofSumyStateUniversity, 2009, Vol.4, pp. 14-21[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/462

K.V. Zheba, V.I. Sklabinskyi, A.E. Artyukhov. Hydrodynamics of diphasic vortical streams. Effect to the granulation equipment size, Chemical industry of Ukraine, 2009, Vol. 4, pp.47-52[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24810

A.E. Artyukhov, V.I. Sklabinskyi.Estimation of possibility of decreasing power expenses at application in production of small vortical granulators, ScientificworksoftheOdessanationalacademyoffoodtechnologies, 2009, Vol.35, pp. 84-87[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/25245

A.E. Artyukhov, V.I. Sklabinskyi.Industrial introduction of vortical type vehicles for the receipt of granular products, ScientificworksoftheOdessanationalacademyoffoodtechnologies, 2008, Vol.32, pp. 16–21[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24614

A.E. Artyukhov, V.M.Marenok, V.I. Sklabinskyi.Complex research of the falseboiling vortex layer and application in technology of mineral fertilizers, Visnyk of Sumy National agrarian university, 2008, Vol. 3 (19), pp.182–185[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/25903

V.I. Sklabinskyi, A.E. Artyukhov. Calculation of hydrodynamic parameters in the twirled streams of the vortical granulators by the analytical method, VisnykofSumyStateUniversity,2008, Vol. 3, pp.62–70[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/1239

A.E. Artyukhov, V.I. Sklabinskyi.Development of the methods of engineering calculation of vortex granulators, Questions of chemistry and chemical technology, 2007, Vol. 5, pp.209–211[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24649

А.E.Аrtyukhov,V.M.Marenok,V.I. Sklabinskyi. Research of false boiling vortex layer forming terms in thesmall mass-exchange devices, VisnykofSumyStateUniversity,2007, Vol. 3, pp.10-17 [in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/1209

V.I. Sklabinskyi, A.E. Artyukhov. Small vehicles of variable to the cut with the vortical weighed layer. Influence of distributive devices on motion of granules, Chemical industry of Ukraine, 2006, Vol. 2 (73), pp. 55-59 [in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24809

A.E. Artyukhov, V.I. Sklabinskyi.Mathematical design of the process of the motion of the granules in the vortical vehicles with small height of the working chamber, VisnykofSumyStateUniversity,2006, Vol. 12 (96), pp. 5–11[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/1347

A.E. Artyukhov. Newest granulation equipment. Vortical granulator with the vibration sawing of fusion, ScientificworksoftheOdessanationalacademyoffoodtechnologies,2006, Vol. 28, pp. 24–27[in Ukrainian] http://essuir.sumdu.edu.ua/handle/123456789/24808

V.I. Sklabinskyi, A.E. Artyukhov. Questions of energy economy at introduction in production of small granulation equipment, VisnykofSumyStateUniversity,2006, Vol. 5 (89), pp.76–79[in Russian] http://essuir.sumdu.edu.ua/handle/123456789/1870

V.I. Sklabinskyi, O.O. Lyaposchenko A.E. Artyukhov. Technological Basics of Oil and Gas Refining Industry, Sumy State University, Sumy, 2011, 187 p.

More publications available for download at: https://www.researchgate.net/profile/Artem_rtyukhov/, http://ua.linkedin.com/pub/artem-artyukhov/3b/87b/5a4, http://essuir.sumdu.edu.ua/

LIST OF PARTICIPATION IN RESEARCH PROJECTS:

2006-2008: Working off the technological and structural parameters of porous granules creation knot and delivery of basic data for planning of setting of receipt of porous ammoniac saltpetre, development of designer document on setting of receipt of porous ammonium nitrate (PAN).

2008-2010: Research of the vortical granulation, mass-transfer and heat-transfer devices.

2010 – present: Research of hydrodynamic, mass-transfer and heat-transfer descriptions with vortical and high turbulence monophase and diphase streams.

RESEARCH PROJECTS

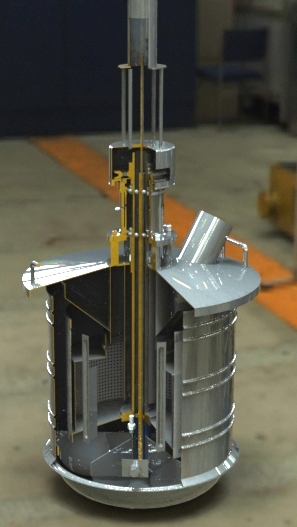

Rotating vibro-granulator

Rotating vibro-granulator is applied in the chemical industry and is intended for dispersion fusion of nitrogen fertilizers on uniform drops in the granulation tower with their following cooling and crystallization into solid granules in the process of a free fall in the up-coming stream of cooling air. Rotating vibro-granulator is intended for production of monodisperse granulated nitrogen (ammoniac saltpeter, carbamide) and complex fertilizers and represents the system of compactly located primary and ancillary equipment, pipelines.

Use of the process of monodispersion brings radical improvement into the technology of fertilizers production. Use of uniform (monodisperse) granules in agriculture allows disseminating fertilizers evenly on the fertilized area and due to this – to get an additional rise of a crop to 10 %.

Vibro-granulators allow receiving firm monodisperse granules with a smooth glossy surface (monodisperse degree - up to 99 %) what stipulates for the possibility of intensification of granulation process and essentially raises agro-technical value of fertilizers.

Rotating vibro-granulator

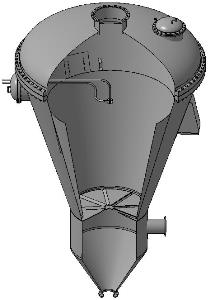

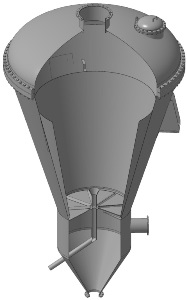

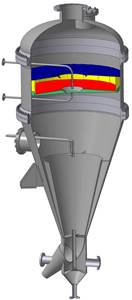

Vortex type granulator with a variable height cross section of the working space

The way of granulation from fusions, solutions and the suspensions is put in a basis of the vortex type granulator with a variable height cross section of the working space functioning, founded on improvement on dynamics of movement a granules stream that provides increase in monodisperseof granules and uniformity granulometricstructure of a prepared product. Vortex type granulator allows receiving the granulated products without application granulation towers which are equipped by difficult and expensive system of communications and have considerable overall dimensions. The developed design of vortex type granulator allows not only to receive granules of the set structure, but also to spend classification of granules by the size.

The basic advantages of the offered device: 1) possibility of reduction of overall dimensions (in particular, heights) working space; 2) time increase of a granule staying in the working space of the vortex type granulator; 3) possibility of traffic control of a granule in working space of the device; 4) creation in the volume of working space of intensive hydrodynamics with high turbulence; 5) universality (possibility of carrying out of granulation and drying processes in volume of one device); 6) simplicity of manufacturing, possibility of fast readjustment and change of constructive and technological parameters according to the set task.

Vortex type granulator with a variable height cross section of the working space

TEACHING EXPERIENCE:

2006–present: Processes and equipment of chemical industry (specialization gas and oil refining productions), Technological bases of gas and oil refining productions, Equipment of gas and oil refining productions, Technological lines and complexes of nitric productions, Technological lines and complexes of chemical productions, Processes and equipment of gas separation, Development of chemical enterprises and bases of САD.

HONORS AND AWARDS:

Scholarship of the Cabinet of Ministers of Ukraine, since September 2012

OTHER ACTIVITIES:

2010–present: Member of working group of pedagogical experiment for determine the student’s aptitudes to research, organizing and performing activities of engineering majors in Sumy State University

september 2011 – july 2012: Deputy Dean of Skills Upgrading and Postgraduate Education Faculty

september 2011–present: Deputy Head of Processes and Equipment of Chemical and Petroleum Refineries Department with the International Relations

september 2011–present: Head of Section «Machines and Equipment of Oil and Gas Industry» at Processes and Equipment of Chemical and Petroleum Refineries Department